Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2012 PMM Sedan

- Thread starter CivicCanuck

- Start date

- Thread starter

- #2

CivicCanuck

Well-Known Member

- Thread starter

- #3

CivicCanuck

Well-Known Member

- Thread starter

- #4

CivicCanuck

Well-Known Member

KennyGS

How may I help?

Nice work! Also looking forward to seeing what else you do.

Nice work! Also looking forward to seeing what else you do.- Thread starter

- #7

CivicCanuck

Well-Known Member

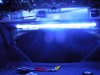

New LED interior lights are bright.

Last edited:

- Thread starter

- #8

CivicCanuck

Well-Known Member

Finally installed the last interior light, it came in the mail on Friday. First two pictures are through the tinted glass.... View attachment 9877View attachment 9878

Last edited:

andre12dbsi

Well-Known Member

Finally installed the last interior light, it came in the mail on Friday. First two pictures are through the tinted glass.... View attachment 9876View attachment 9877View attachment 9878View attachment 9879View attachment 9880

Looks good. Really bright even through the tint.

KennyGS

How may I help?

Nice... bright.

rs1customs

Well-Known Member

Very nice

- Thread starter

- #12

CivicCanuck

Well-Known Member

Well today was kind of a bust, drove to my hometown to get in my brother's shop, but it was tied up again, a friend of mine was changing out the transmission on his pickup. I did manage to do some soldering and prep in order to install extra trunk lighting, maybe I will see if I can squeak my car into my work tomorrow and wire them up.  <BR> Tools of the trade: Solder, soldering iron, heat gun, heat shrink tubing in various sizes, electrical tape, wire cutters, wire strippers, olfa knife and 18 gauge primary wire.

<BR> Tools of the trade: Solder, soldering iron, heat gun, heat shrink tubing in various sizes, electrical tape, wire cutters, wire strippers, olfa knife and 18 gauge primary wire.  <BR> Strip back about 3/4" of the insulation of the wires you are joining.

<BR> Strip back about 3/4" of the insulation of the wires you are joining.  <BR> Install heat shrink tubing over the wire, and twist the bare ends tightly together.

<BR> Install heat shrink tubing over the wire, and twist the bare ends tightly together.  <BR> This is what the wires should look like when twisted together tightly, with no loose strands, resulting in a connection that you can pull on slightly without the twist coming apart.

<BR> This is what the wires should look like when twisted together tightly, with no loose strands, resulting in a connection that you can pull on slightly without the twist coming apart.  <BR> It is important to clean the tip thoroughly between solder joints, a damp sponge works well for this, I didn't have one but heating the tip up and applying new solder to it before making a joint cleans the tip as well.

<BR> It is important to clean the tip thoroughly between solder joints, a damp sponge works well for this, I didn't have one but heating the tip up and applying new solder to it before making a joint cleans the tip as well.  <BR> Apply the clean, hot tip to the wire joint, and let the heat from the tip warm the joint, once the joint has reached the correct temperature, apply solder. In order to make a nice joint that isn't cold, the wire should melt the solder, not the tip.

<BR> Apply the clean, hot tip to the wire joint, and let the heat from the tip warm the joint, once the joint has reached the correct temperature, apply solder. In order to make a nice joint that isn't cold, the wire should melt the solder, not the tip.  <BR> After letting the completed joint cool ( should be nice and shiny, not dull which would indicate a slushy, cold solder joint ) slide the heat shrink tubing over the joint, making sure it's centered and apply heat from heat gun. The completed joint should look nice and smooth, and if you used the correct size heat shrink tubing there should be no gaps between the tubing and the wire jacket.

<BR> After letting the completed joint cool ( should be nice and shiny, not dull which would indicate a slushy, cold solder joint ) slide the heat shrink tubing over the joint, making sure it's centered and apply heat from heat gun. The completed joint should look nice and smooth, and if you used the correct size heat shrink tubing there should be no gaps between the tubing and the wire jacket.

<BR> Tools of the trade: Solder, soldering iron, heat gun, heat shrink tubing in various sizes, electrical tape, wire cutters, wire strippers, olfa knife and 18 gauge primary wire.

<BR> Tools of the trade: Solder, soldering iron, heat gun, heat shrink tubing in various sizes, electrical tape, wire cutters, wire strippers, olfa knife and 18 gauge primary wire.  <BR> Strip back about 3/4" of the insulation of the wires you are joining.

<BR> Strip back about 3/4" of the insulation of the wires you are joining.  <BR> Install heat shrink tubing over the wire, and twist the bare ends tightly together.

<BR> Install heat shrink tubing over the wire, and twist the bare ends tightly together.  <BR> This is what the wires should look like when twisted together tightly, with no loose strands, resulting in a connection that you can pull on slightly without the twist coming apart.

<BR> This is what the wires should look like when twisted together tightly, with no loose strands, resulting in a connection that you can pull on slightly without the twist coming apart.  <BR> It is important to clean the tip thoroughly between solder joints, a damp sponge works well for this, I didn't have one but heating the tip up and applying new solder to it before making a joint cleans the tip as well.

<BR> It is important to clean the tip thoroughly between solder joints, a damp sponge works well for this, I didn't have one but heating the tip up and applying new solder to it before making a joint cleans the tip as well.  <BR> Apply the clean, hot tip to the wire joint, and let the heat from the tip warm the joint, once the joint has reached the correct temperature, apply solder. In order to make a nice joint that isn't cold, the wire should melt the solder, not the tip.

<BR> Apply the clean, hot tip to the wire joint, and let the heat from the tip warm the joint, once the joint has reached the correct temperature, apply solder. In order to make a nice joint that isn't cold, the wire should melt the solder, not the tip.  <BR> After letting the completed joint cool ( should be nice and shiny, not dull which would indicate a slushy, cold solder joint ) slide the heat shrink tubing over the joint, making sure it's centered and apply heat from heat gun. The completed joint should look nice and smooth, and if you used the correct size heat shrink tubing there should be no gaps between the tubing and the wire jacket.

<BR> After letting the completed joint cool ( should be nice and shiny, not dull which would indicate a slushy, cold solder joint ) slide the heat shrink tubing over the joint, making sure it's centered and apply heat from heat gun. The completed joint should look nice and smooth, and if you used the correct size heat shrink tubing there should be no gaps between the tubing and the wire jacket.

Last edited:

- Staff

- #13

- 55,560

- 23,825

Nice seeing a lx build

rs1customs

Well-Known Member

Very nice

- Thread starter

- #15

CivicCanuck

Well-Known Member

Today was super nice out, and I got my car into the shop at work. Got the trunk auxiliary lighting installed, all the connections soldered, heat shrink, covered in 1/4" loom and taped. Had to pull out the rear package tray, and the side panels in order to run the wire to the factory trunk light. There was no @#$% way to snake wire through, I tried every trick in the book to run it under the rear package tray, but finally ended up taking it out to run the wire, and it made life so much easier.  <BR> Measure the width of the mounting areas, I had to cut about 5 inches off of one strip, and about 3 off of the other. You can cut the strips in between every 3 LED's. Measure the center of the shortened strip, this will allow you to center them, so that they look symmetrical, and it doesn't look like a 5 year old did the work.

<BR> Measure the width of the mounting areas, I had to cut about 5 inches off of one strip, and about 3 off of the other. You can cut the strips in between every 3 LED's. Measure the center of the shortened strip, this will allow you to center them, so that they look symmetrical, and it doesn't look like a 5 year old did the work. <BR>Holding in on the center, peel the backing from one side of the strip, and carefully stick the tape down.

<BR>Holding in on the center, peel the backing from one side of the strip, and carefully stick the tape down.  <BR> Should look nice and even like this.

<BR> Should look nice and even like this.  <BR> Like a kid in a candy store, I had to jam the wires into the plug for the factory trunk light to see what it was going to be like lit up, this is only one strip.

<BR> Like a kid in a candy store, I had to jam the wires into the plug for the factory trunk light to see what it was going to be like lit up, this is only one strip.  >BR> From inside the trunk.

>BR> From inside the trunk.  <BR> Both strips lit up.

<BR> Both strips lit up.  <BR> I ended up shortening the wires I added to the one strip and "T'd" them into the other wires, which will get connected to the factory trunk light wiring.

<BR> I ended up shortening the wires I added to the one strip and "T'd" them into the other wires, which will get connected to the factory trunk light wiring.  <BR> To make a T or Y in wiring, without cutting the wire, carefully strip a section of jacket material, and strip the other wire you are going to join. Slide a piece of heat shrink tubing over the wire, twist them together and solder your connection. Slide the heatshrink over the cooled solder joint, and then hit it with a heat gun.

<BR> To make a T or Y in wiring, without cutting the wire, carefully strip a section of jacket material, and strip the other wire you are going to join. Slide a piece of heat shrink tubing over the wire, twist them together and solder your connection. Slide the heatshrink over the cooled solder joint, and then hit it with a heat gun.  <BR> Had to remove the rear package tray to fish the wire up through the small hole at the very back on the driver's side. Tied it to the factory wire with tie-wraps and tape.

<BR> Had to remove the rear package tray to fish the wire up through the small hole at the very back on the driver's side. Tied it to the factory wire with tie-wraps and tape.

Trunk liner pulled back, can you tell which wires were added?

<BR> Measure the width of the mounting areas, I had to cut about 5 inches off of one strip, and about 3 off of the other. You can cut the strips in between every 3 LED's. Measure the center of the shortened strip, this will allow you to center them, so that they look symmetrical, and it doesn't look like a 5 year old did the work.

<BR> Measure the width of the mounting areas, I had to cut about 5 inches off of one strip, and about 3 off of the other. You can cut the strips in between every 3 LED's. Measure the center of the shortened strip, this will allow you to center them, so that they look symmetrical, and it doesn't look like a 5 year old did the work. <BR>Holding in on the center, peel the backing from one side of the strip, and carefully stick the tape down.

<BR>Holding in on the center, peel the backing from one side of the strip, and carefully stick the tape down.  <BR> Should look nice and even like this.

<BR> Should look nice and even like this.  <BR> Like a kid in a candy store, I had to jam the wires into the plug for the factory trunk light to see what it was going to be like lit up, this is only one strip.

<BR> Like a kid in a candy store, I had to jam the wires into the plug for the factory trunk light to see what it was going to be like lit up, this is only one strip.  >BR> From inside the trunk.

>BR> From inside the trunk.  <BR> Both strips lit up.

<BR> Both strips lit up.  <BR> I ended up shortening the wires I added to the one strip and "T'd" them into the other wires, which will get connected to the factory trunk light wiring.

<BR> I ended up shortening the wires I added to the one strip and "T'd" them into the other wires, which will get connected to the factory trunk light wiring.  <BR> To make a T or Y in wiring, without cutting the wire, carefully strip a section of jacket material, and strip the other wire you are going to join. Slide a piece of heat shrink tubing over the wire, twist them together and solder your connection. Slide the heatshrink over the cooled solder joint, and then hit it with a heat gun.

<BR> To make a T or Y in wiring, without cutting the wire, carefully strip a section of jacket material, and strip the other wire you are going to join. Slide a piece of heat shrink tubing over the wire, twist them together and solder your connection. Slide the heatshrink over the cooled solder joint, and then hit it with a heat gun.  <BR> Had to remove the rear package tray to fish the wire up through the small hole at the very back on the driver's side. Tied it to the factory wire with tie-wraps and tape.

<BR> Had to remove the rear package tray to fish the wire up through the small hole at the very back on the driver's side. Tied it to the factory wire with tie-wraps and tape.

Trunk liner pulled back, can you tell which wires were added?

Last edited:

Pauly99to17

Well-Known Member

looks great....Certainly bright enough. I like!

Last edited:

- Thread starter

- #17

CivicCanuck

Well-Known Member

<BR> Barely visible, unless you are crouched right down. The tape is 0.120 inch thick, so just a hair less than 1/8th".

<BR> Barely visible, unless you are crouched right down. The tape is 0.120 inch thick, so just a hair less than 1/8th".  <BR> Looking up from the trunk floor. This last picture was taken in the dark with no other light, no flash. Sweeeeeet..... now to install the JL Stealthbox, amp, wiring, and underhood lighting I have planned.

<BR> Looking up from the trunk floor. This last picture was taken in the dark with no other light, no flash. Sweeeeeet..... now to install the JL Stealthbox, amp, wiring, and underhood lighting I have planned.

Last edited:

- Thread starter

- #18

CivicCanuck

Well-Known Member

Start to finish today, from sticking the first strip on to clean up all the tools, wash the car, vacuum out the trunk was about 3 1/2 hours, that includes stopping to take pictures along the way.

KennyGS

How may I help?

Great work!

I took the same amount of time to do my taxes today.

Your time looked better spent.

I took the same amount of time to do my taxes today.

Your time looked better spent.

- Thread starter

- #20

CivicCanuck

Well-Known Member

Thanks... it's a good thing I am still fairly flexible, as most of that time was spent on my back, with my neck bent in funny positions. Getting in and out of the trunk about 15-20 times sucked.