Alright so I've been searching the internet for awhile on random things and came across an interesting set of videos that I figured i would share with you.

The info may be already known by most but i found them to be great watches if you have time, I personally learned a handful.

Now at around 23 min or so in Tech Talk 1, Banks talks about how he achieved higher Intake Density (ID) by a simple cold ram air intake duct. My brain started to turn from here on as i watched all 3 videos.

Do YOU think a cold ram scoop on the civic while using the FACTORY air box is worth it?

I personally think it would be the most beneficial mod we could do to an already top preforming intake vs aftermarket as been proven.

So how can i make this possible...my first thought was right to the drivers fog light garnish. I was a little lost at this point on how this could be possible since i haven't dug into the car personally. A few days go by and then i stumbled upon the DIY for the resonator delete and i see how doable this actually could be.

http://9thcivic.com/forum/threads/resonator-delete-si-sedan.4811/ (the DIY if you dont know what your looking at here)

The opening left after the resonator delete is more than sufficient to fabricate a scoop to feed into the intake tube.

Below are a few pics of my Coupe with the garnish removed. You can see where my resonator is still installed which is where the scoop will route to as seen above.

Off the bat i noticed that the horn WILL need to removed completely or relocated one way or another as it is in the way. Hard to tell from the picture but a smooth design is not possible with the horn there. The other "problem" is the aluminium crash bar that obviously limits the scoop opening. I still feel there to be more than enough room to still allow good ram air.

I was also thinking of using my (or if i could buy someones off them ) resonator piping that you remove in doing the delete so the connection to the intake tube is sealed as well as a good base to build the scoop off of. Ideal portion is circled below

) resonator piping that you remove in doing the delete so the connection to the intake tube is sealed as well as a good base to build the scoop off of. Ideal portion is circled below

My next obstacle is modifying the drivers fog light garnish. I'm gonna order one from @CollegeHillsHonda so i don't screw up my original one if i make a mistake or decide to scrap the idea at some point. Gotta support the vendors!

The modification to the bezel is basically cutting out an opening to allow air to actually flow around the fog light. My thought is to just cut out each diamond in the pattern but leave the "cage" look to it. Example below

The exact amount and which ones i would need to cut would be determined but you get the idea. i would then put a screen lining behind it to keep it from a bug/debris ram.

The last problem that i had to figure out to start making this idea a tangible outcome was the material to use. I'm still not 100% as I'm open to any and all ideas if you think of something better BUT i was leaning towards something like this...

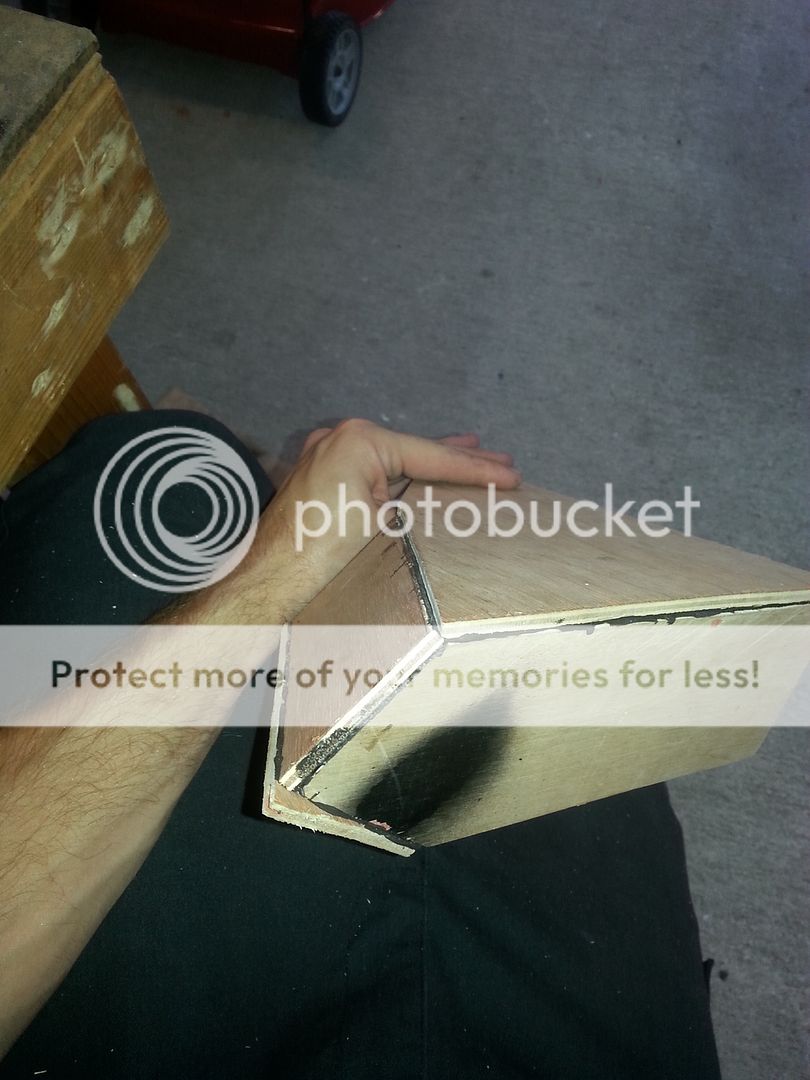

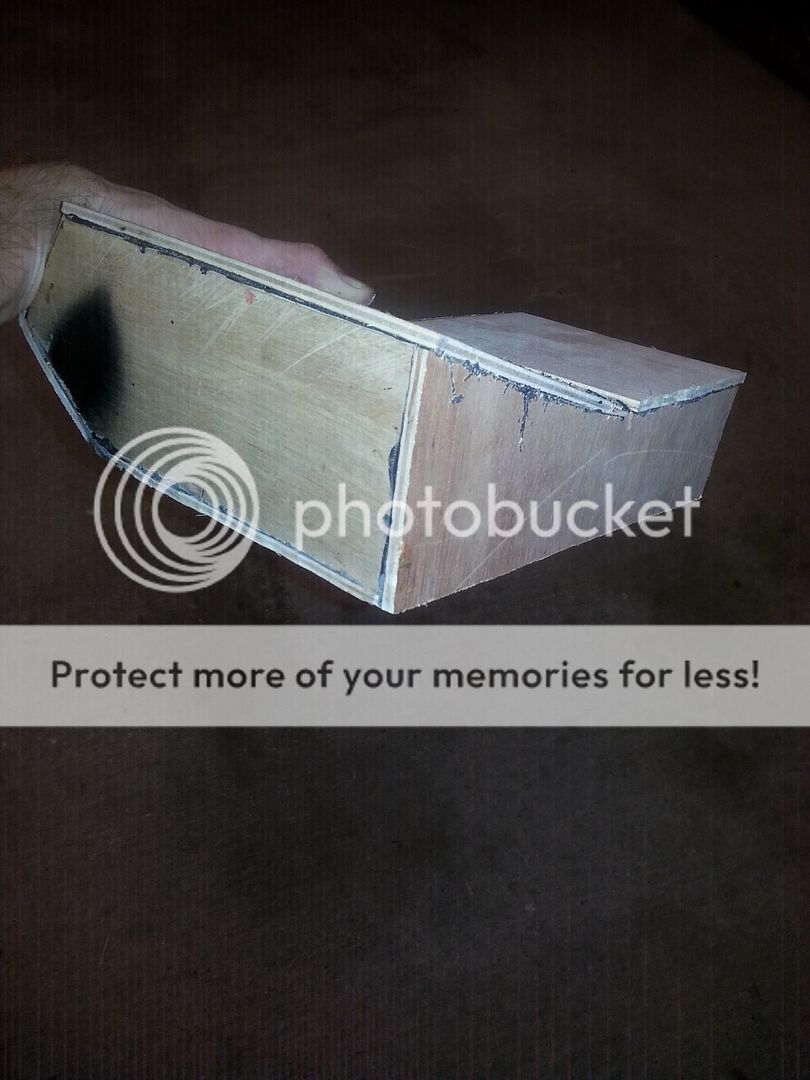

My idea is to build a balsa wood/fiberglass duct. Seems plenty strong enough for vibrations, won't absorb water, relatively inexpensive(guessing as i have not looked up material prices yet).

I'm not sure if this has been thought of or attempted yet but i LOVE trying new DIY mods and building things with my hands so I'm determined to make this possible. Figured i would share my random and crazy idea and welcome any thoughts/criticism that could help this be productive.

The info may be already known by most but i found them to be great watches if you have time, I personally learned a handful.

Now at around 23 min or so in Tech Talk 1, Banks talks about how he achieved higher Intake Density (ID) by a simple cold ram air intake duct. My brain started to turn from here on as i watched all 3 videos.

Do YOU think a cold ram scoop on the civic while using the FACTORY air box is worth it?

I personally think it would be the most beneficial mod we could do to an already top preforming intake vs aftermarket as been proven.

So how can i make this possible...my first thought was right to the drivers fog light garnish. I was a little lost at this point on how this could be possible since i haven't dug into the car personally. A few days go by and then i stumbled upon the DIY for the resonator delete and i see how doable this actually could be.

http://9thcivic.com/forum/threads/resonator-delete-si-sedan.4811/ (the DIY if you dont know what your looking at here)

The opening left after the resonator delete is more than sufficient to fabricate a scoop to feed into the intake tube.

Below are a few pics of my Coupe with the garnish removed. You can see where my resonator is still installed which is where the scoop will route to as seen above.

Off the bat i noticed that the horn WILL need to removed completely or relocated one way or another as it is in the way. Hard to tell from the picture but a smooth design is not possible with the horn there. The other "problem" is the aluminium crash bar that obviously limits the scoop opening. I still feel there to be more than enough room to still allow good ram air.

I was also thinking of using my (or if i could buy someones off them

) resonator piping that you remove in doing the delete so the connection to the intake tube is sealed as well as a good base to build the scoop off of. Ideal portion is circled below

) resonator piping that you remove in doing the delete so the connection to the intake tube is sealed as well as a good base to build the scoop off of. Ideal portion is circled below

My next obstacle is modifying the drivers fog light garnish. I'm gonna order one from @CollegeHillsHonda so i don't screw up my original one if i make a mistake or decide to scrap the idea at some point. Gotta support the vendors!

The modification to the bezel is basically cutting out an opening to allow air to actually flow around the fog light. My thought is to just cut out each diamond in the pattern but leave the "cage" look to it. Example below

The exact amount and which ones i would need to cut would be determined but you get the idea. i would then put a screen lining behind it to keep it from a bug/debris ram.

The last problem that i had to figure out to start making this idea a tangible outcome was the material to use. I'm still not 100% as I'm open to any and all ideas if you think of something better BUT i was leaning towards something like this...

My idea is to build a balsa wood/fiberglass duct. Seems plenty strong enough for vibrations, won't absorb water, relatively inexpensive(guessing as i have not looked up material prices yet).

I'm not sure if this has been thought of or attempted yet but i LOVE trying new DIY mods and building things with my hands so I'm determined to make this possible. Figured i would share my random and crazy idea and welcome any thoughts/criticism that could help this be productive.

Last edited:

I'm not too sure it's going to be worth it myself BUT thats where the fun for me is. Creating a custom mod and learning.

I'm not too sure it's going to be worth it myself BUT thats where the fun for me is. Creating a custom mod and learning.

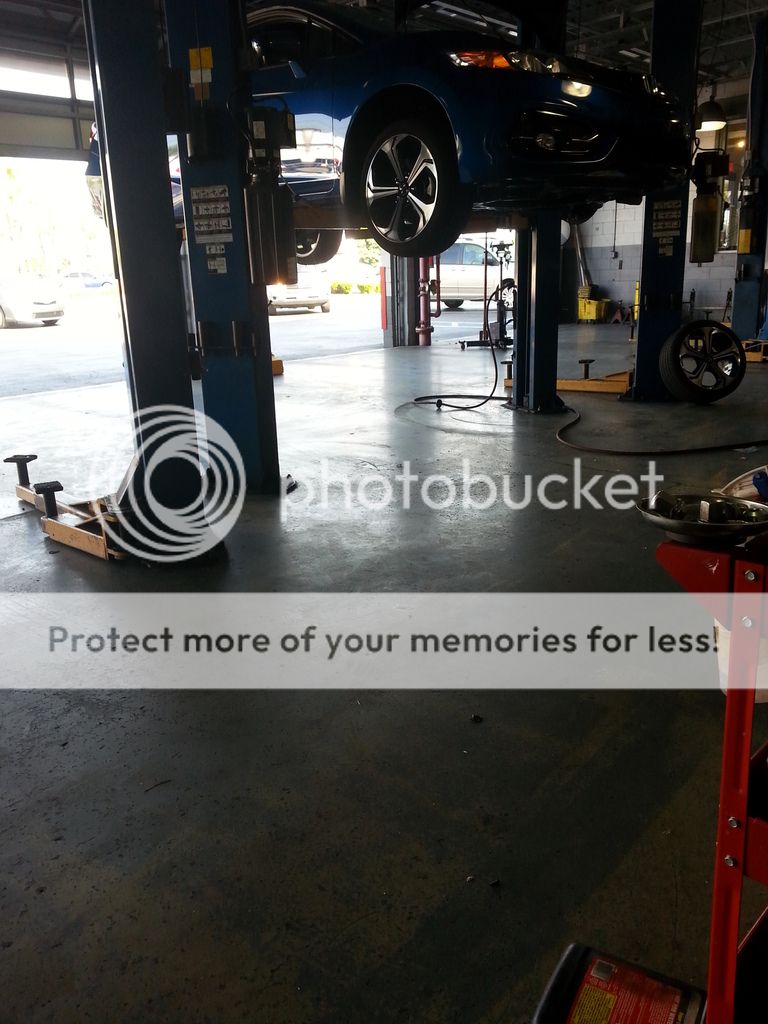

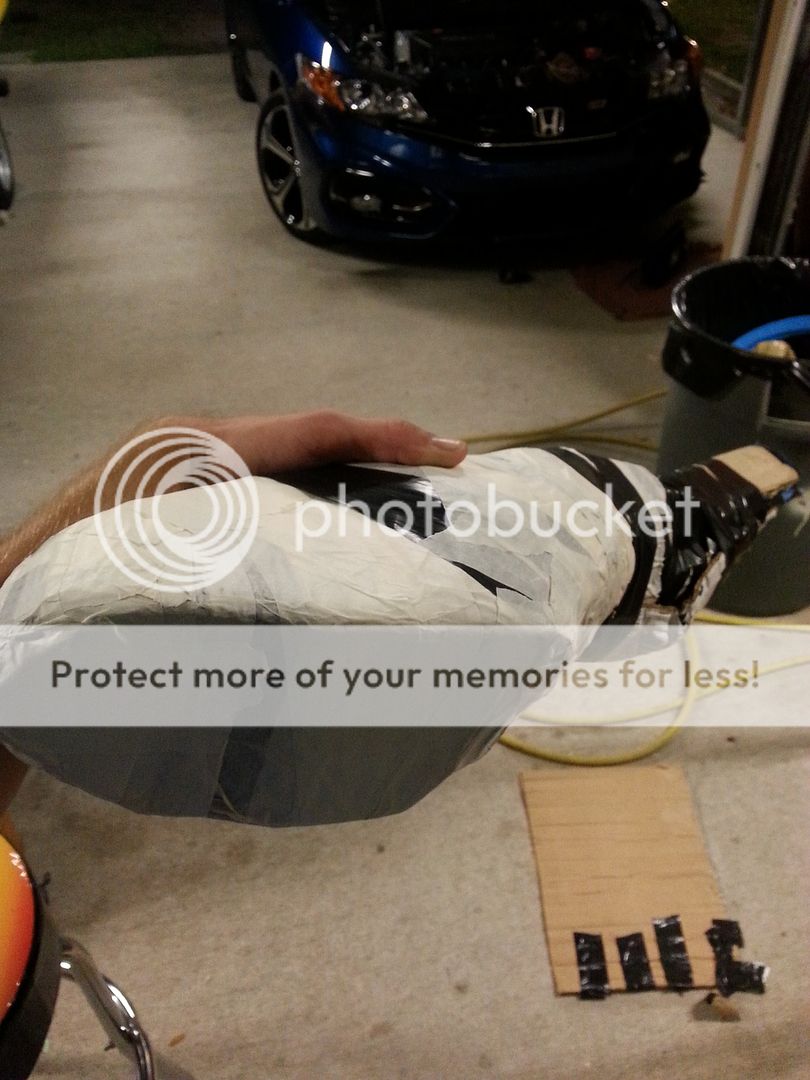

) and my first attempt at a mock up. I was the only one in the shop at this time. *Side note* HOLLY HEAVY BATMAN! My 99 jeep grand cherokee had lighter rim/tire package from factory. Why do manufactures go this route now

) and my first attempt at a mock up. I was the only one in the shop at this time. *Side note* HOLLY HEAVY BATMAN! My 99 jeep grand cherokee had lighter rim/tire package from factory. Why do manufactures go this route now

Happy Times!

Happy Times!

I'm debating to modify the front scoop with a lower channel to increase amount of captured air flow, i'll try to mark what I'm talking about.

I'm debating to modify the front scoop with a lower channel to increase amount of captured air flow, i'll try to mark what I'm talking about.

lol

lol