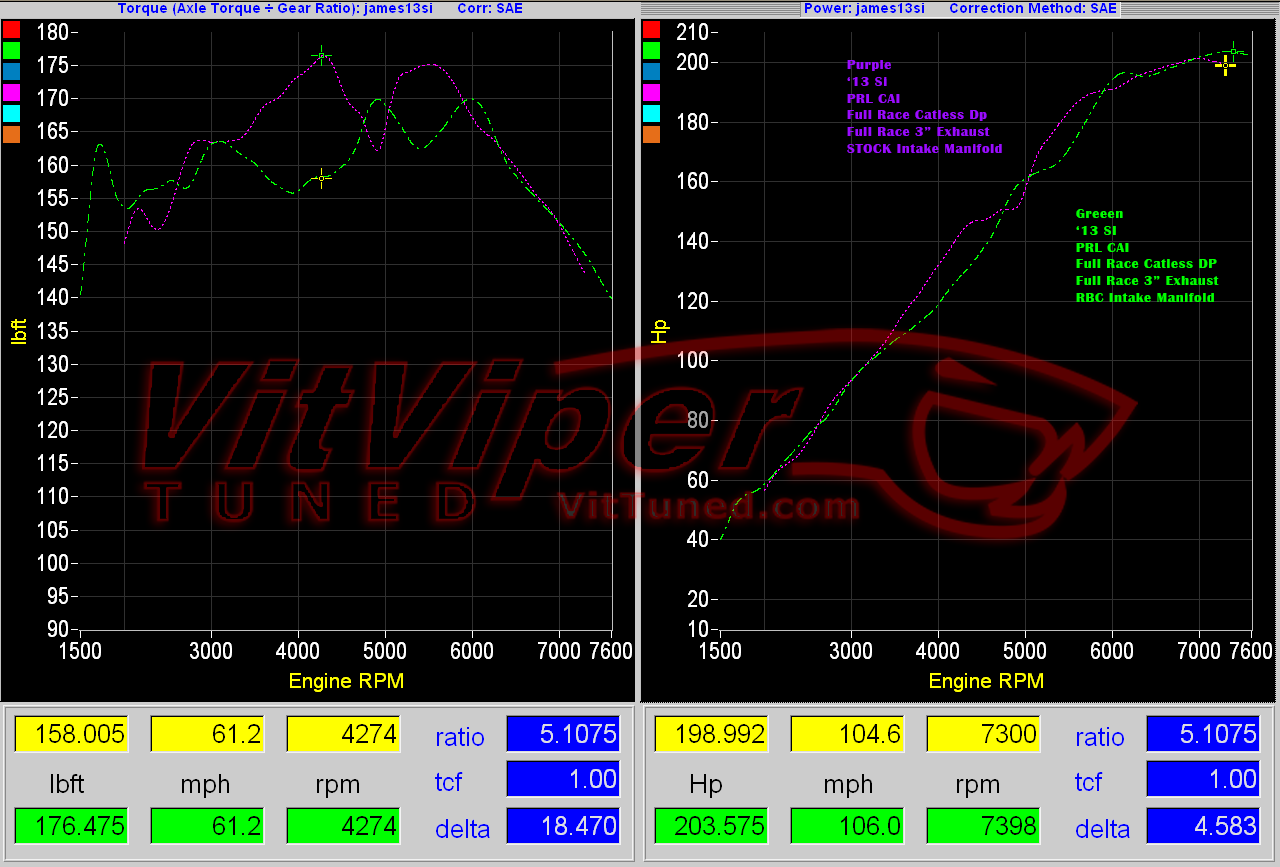

there's a whole lot more that goes into intake manifold design than most people realize. one thing that affects performance is resonance caused by the pressure waves created as the intake valves open and close. a properly designed manifold can use those waves to the engine's benefit, maximizing the intake charge at the moment the intake valve opens. For high RPM motors, the problem is finding the sweet spot. the resonance frequency at low RPM is not the same as the resonance frequency at high RPM, so traditionally, manifold design was a compromise between choosing good low RPM torque or good high RPM power. Honda's old B-series motors were designed more for the latter. One solution that some manufacturers (including Honda) have come up with is variable length intake runners (which is also one reason for the increased prevalence of plastic intake manifolds). Not sure if the Si's motor has the variable length intake runners that Honda used in some other k24s, but it could one reason why the OEM manifold seems to be better across the whole range when compared to the RBC.

King Motorsports actually had a good article that simplifies the principle of these wave dynamics on their website:

"When the valve opens, the air in the runner and port decompresses into the low-pressure region (the cylinder and combustion chamber). The air on the upstream side of the port is completely isolated and unaffected by what happens on the downstream side of it until the valve opens, allowing the compressed air at the valve to flow in, sending a wave back up the port. The air at the runner entrance does not move until that wave reaches all the way to the end. Up to that point all that happens is the higher pressure gas filling the volume of the runner/port decompresses or expands into the low-pressure region advancing up the runner. Once the low pressure wave reaches the open end of the runner it reverses direction, and the inrushing air forces a high pressure wave down the runner. Conversely the closing of the valve does not immediately stop flow at the runner entrance, which continues completely unaffected until the signal that the valve has closed reaches it. The closing valve causes a buildup of pressure which will travel up the runner as a positive wave. The runner entrance continues to flow at full speed, forcing the pressure to rise until the signal reaches the entrance. At the closing of the intake valve, pressure rises far above atmospheric. It is this phenomenon that enables the so-called "ram tuning" to occur and it is what is being "tuned" by tuned intake and exhaust systems. The speed that the signal can travel is the speed of sound in the gas inside the runner. This is why port/runner volumes are so important; the volumes of successive parts of the port/runner control the flow during all transient periods. That is, any time a change occurs in the cylinder - whether positive or negative - such as when the piston reaches maximum speed. At first glance this wave travel might seem to be blindingly fast, but calculations show the opposite is true. In an intake runner at room temperature the sonic speed is about 1,100 feet per second (340 m/s) and will traverse a 12-inch (300 mm) port/runner in 0.9 milliseconds. The engine using this system, running at 8500 rpm, takes a very considerable 46 crank degrees before any signal from the cylinder can reach the runner end. 46 degrees during which nothing but the volume of the port/runner supplies the demands of the cylinder. Why not eliminate the delay with short ports? At the end of the cycle when that big long runner now continues to flow at full speed disregarding the rising pressure in the cylinder and providing pressure to the cylinder when it is needed most. The runner length also controls the timing of the returning waves and cannot be altered (except with OEM variable runner intakes, like the Acura Integra GSR). A shorter runner would flow earlier but also would die earlier while returning the positive waves much too quickly and those waves would be weaker. The key is to find the optimum balance of all the factors for the engine requirements. When the valve closes, it causes a pile up of gas giving rise to a strong positive wave which must travel up the runner. The wave activity in the port/runner does not stop but continues to reverberate for some time. When the valve next opens, the remaining waves influence the next cycle. The goal of tuning is to arrange the runners and valve timing so that there is a high-pressure wave in the port during the opening of the intake valve to get flow going quickly and then to have a second high pressure wave arrive just before valve closing in order to fill the cylinder as much as possible. The first wave will be what is left in the runner from the previous cycle while the second will primarily be one created during the current cycle by the suction wave changing sign at the runner entrance and arriving back at the valve in time for valve closing."